For applications in grooves对于应用在沟槽

Several types of O-profiles have been developed for different applications, each with their own benefits. O-profiles were developed for high performance shielding mainly for military applications. They are used where environmental and EMI screening is required but were little space is available.

几个类型的O-形剖面图垫圈发展用于不同的应用,每个有它们自己的好处。O-形发展用于高性能屏蔽主要用于军事应用。它们被用于环境和EMI屏蔽被要求,但只有很小的空间可利用的地方。

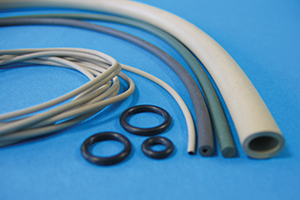

Four kinds of cores are available: solid, hollow extrusion, cell rubber and small rectangular shapes. These can be covered with metallized fabric foils or made out of conductive rubber. For optimal shielding performance a compression of 5-10% is recommended for solid elastomers and 10-50% for hollow extrusions and cell rubbers.

四种核芯可用:实心的,空心管状挤压成形的,单元橡胶和小的矩形形状。这些能用金属化织物薄片覆着或用导电橡胶制造出。为了优化屏蔽性能,一个5-10%的压缩被推荐用于实心弹性体和10-15%用于空心挤出成形和单元橡胶。

How to use如何使用

Solid elastomers are almost not compressible. They are easily deformed but do not change in volume as do sponge elastomers (PVC, EPDM, Neoprene) (See picture below). Therefore, allowance for material flow must be considered in the groove design.

实心弹性体几乎是没有压缩的。它们是容易变形的但不改变体积,此时做海绵弹性体(PVC聚氯乙烯, EPDM三元乙丙橡胶, Neoprene氯丁橡胶) (看图片如下).因此,用于材料流动的公差必须被考虑在沟槽的设计里。